More on bicycle lanes

Portland had a bicycle accident on Thursday that resulted from a right turning cement truck hitting a cyclist who was going straight in the bicycle lane. This has prompted a response from many of my favorite blogs.

Beth Hamon wrote a great piece questioning the use of bicycle lanes on very busy arterials. This resonated with me:

Striping West Burnside — one of Portland’s busiest streets — with a bike lane is a bad idea. Allowing bicyclists to occupy a driver’s blind spot (alongside the car) means they run the risk of getting hit if the driver doesn’t see them. This is not a question of fault. This is a question of poor planning that can and should be fixed. Lose the bike lane, post a lower speed limit and instruct bicyclists to *take the lane* in front of or behind the motor vehicle so that they can be seen. If this doesn’t work — either because cars and bikes won’t play nice there, or because West Burnside eventually becomes the higher-speed backdoor to Beaverton known as Cornell Road, then reconsider the function of such higher-volume, higher-speed roads. Bikes belong some places better than cars do. Cars belong some places better than bikes do. This isn’t rocket science. It’s planning, and until there are no more cars in the world that planning has to work both ways.

Portland is in a unique position (for a medium/large city in the US) of having bicycle lanes everywhere. Perhaps they have too many? Does it do a disservice to cyclists to try and isolate them from all car traffic? I’d argue that it does — cyclists need to understand how to safely get through intersections. Bike lanes don’t help here.

Kent Peterson followed up with an entry coining the term suicide slot:

If you look at Michael Bluejay’s spot (and I really hope I’ve convinced you to take the time to look at it), you’ll see that several of those ten common crashes involve the cyclist being where the driver isn’t looking and/or being in the driver’s blind spot. I call this the “suicide slot”, being to the right of a right turning car.

Now you may say “suicide slot” is a loaded term, that I’m blaming the victim, that the driver should see the cyclist. Well, we can talk about what drivers should do, but as near as I can tell not everybody does what they “should” do. So even even they “should” look to the right,I’m thinking some won’t. And if I’m off to their right anyway,well that strikes me as suicidal. But maybe it is a loaded term. Loaded like a gun. And like a gun, it can kill you.

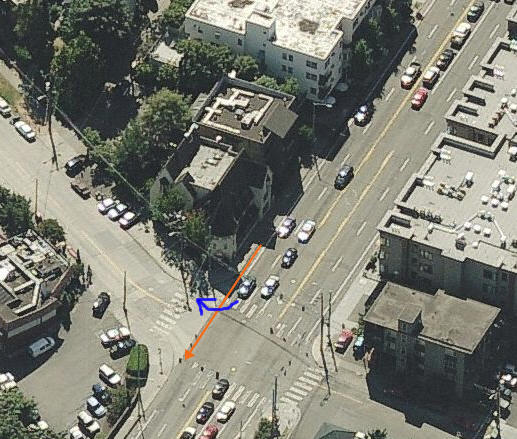

A couple of months ago John Speare posted a photo of a great sign in Redmond that tries to warn about the Suicide Slot:

I like this sign. It is better to have the lanes properly stripped (or not there at all), but this gets across the message in a easy to understand graphic. I don’t think that having this sign everywhere would help, but having it at a few key intersections will pass along some education in an easy to digest form. I’d like to see this sign at Eastlake and Furhman.

At work we have an internal mailing list that cyclists communicate on. Yesterday someone posted a slide deck from New York City showing their new bike lane plan. It puts parked cars as a buffer between the bike lane and car traffic. This is a common practice in some parts of Europe too.

I don’t like this design. It assumes that there are no intersections.

My first observation when I see this graphic is that the bike lane just before 18th is lining up to put bicycles in the suicide slot to the left of left turning cars. My second observation is that bicycles are completely trapped if they want to turn right onto 19th.

The deck says that NYC solves this problem with bicycle only signals. That is a solution that doesn’t scale. When you start having roads with this design intersect other roads with the same design you end up with twice as many signals. For every car signal (straight, turn only in each direction) you end up with a bicycle signal.

It isn’t practical to isolate bicycles from cars in most situations. Bicycle Paths (like Seattle’s Burke Gilman Trail) work because they are generally located on rights of way that already had few intersections and where most of the remaining intersections are at different grades (the bike path passes above or below the road). That isn’t something that can be built along every road.

Drivers and cyclists need basic education on how to ride safely on the same roads. Bike lanes need to be striped to avoid the suicide slot. Speed limits need to be enforced so that 30mph arterials don’t turn into 50mph highways.

Ride safely out there.